Research Projects

Explore available research opportunities

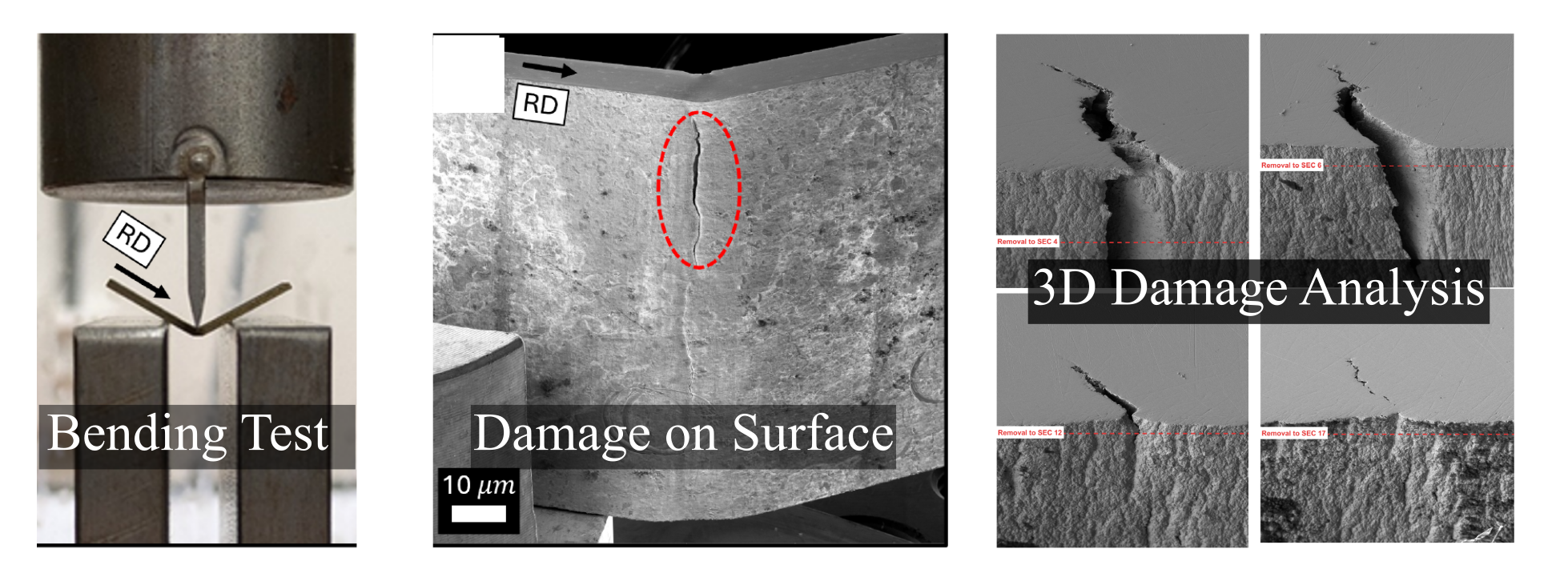

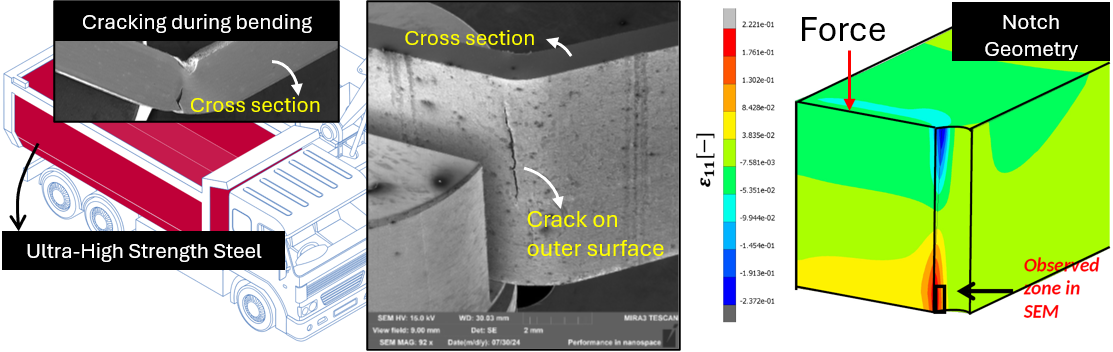

3D Damage Characterization - What's going on under the steel surface?

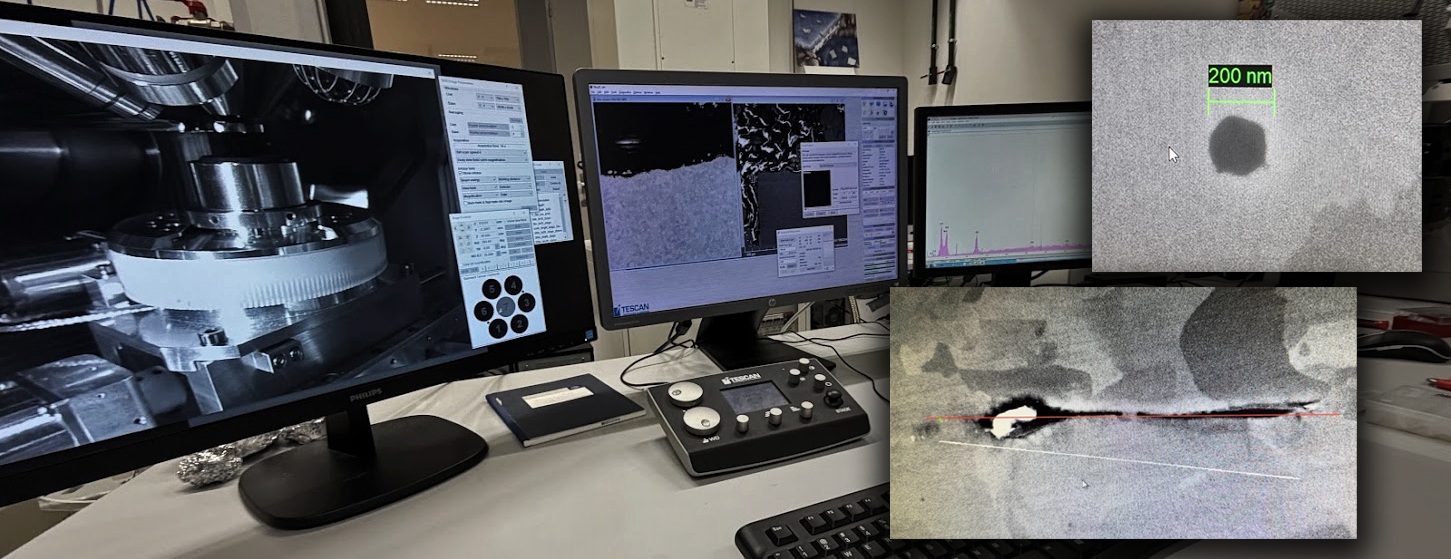

Cracks during bending are of critical importance, but using regular microscopy we can only see what's going on at the surface. This experimental project will focus on characterizing damage in 3D using serial sectioning and electron microscopy.

Analyzing the sensitivity of a cluster dynamics model

A cluster dynamics model will be used to study the effect of neutron irradiation on the evolution of the microstructure and the resulting properties of aluminum alloys for structural components of nuclear research reactors.

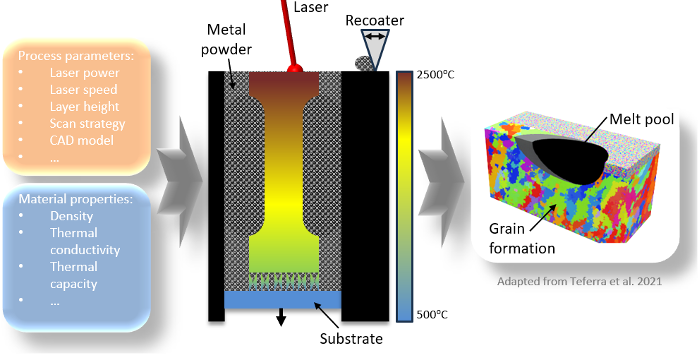

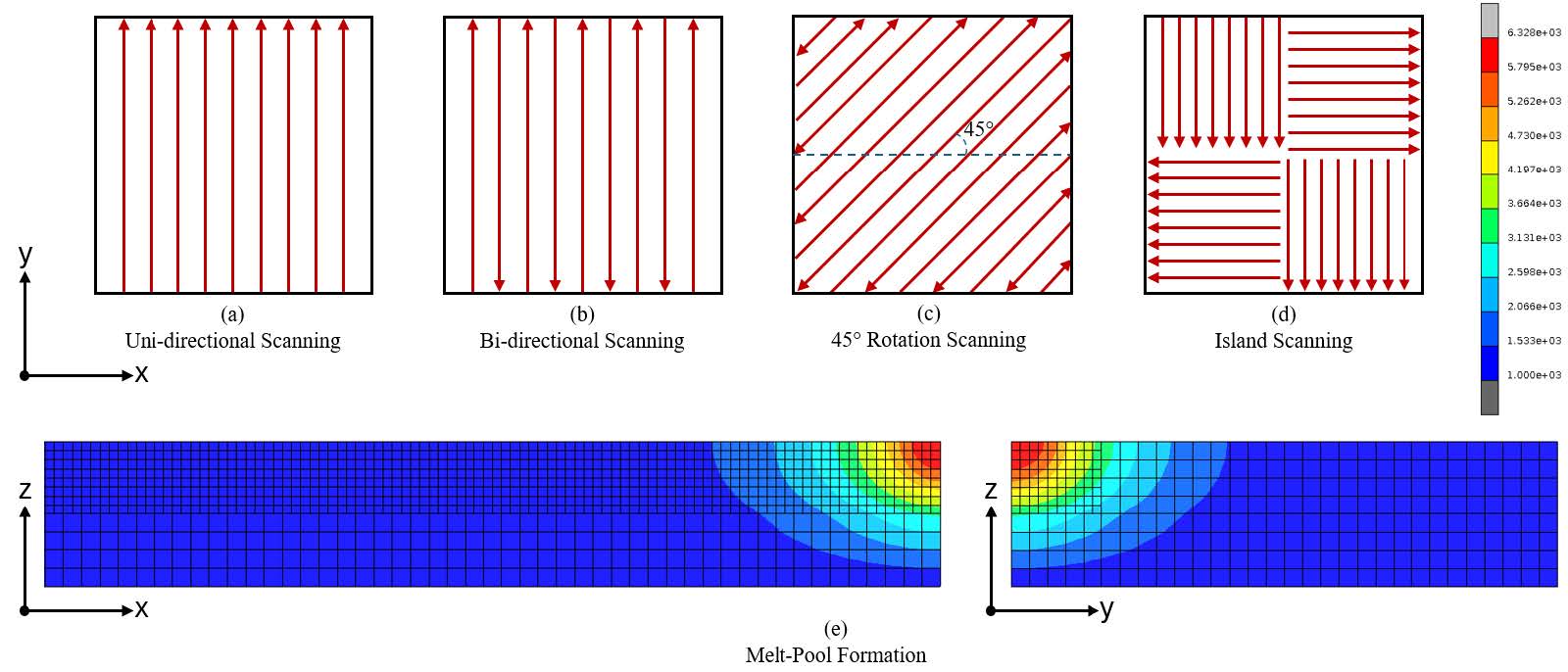

Layer by layer temprature field study of Additively Manufactured Tungsten using LPBF for Fusion Applications

A part-scale model for additive manufacturing of tungsten components for nuclear fusion applications will be developed.

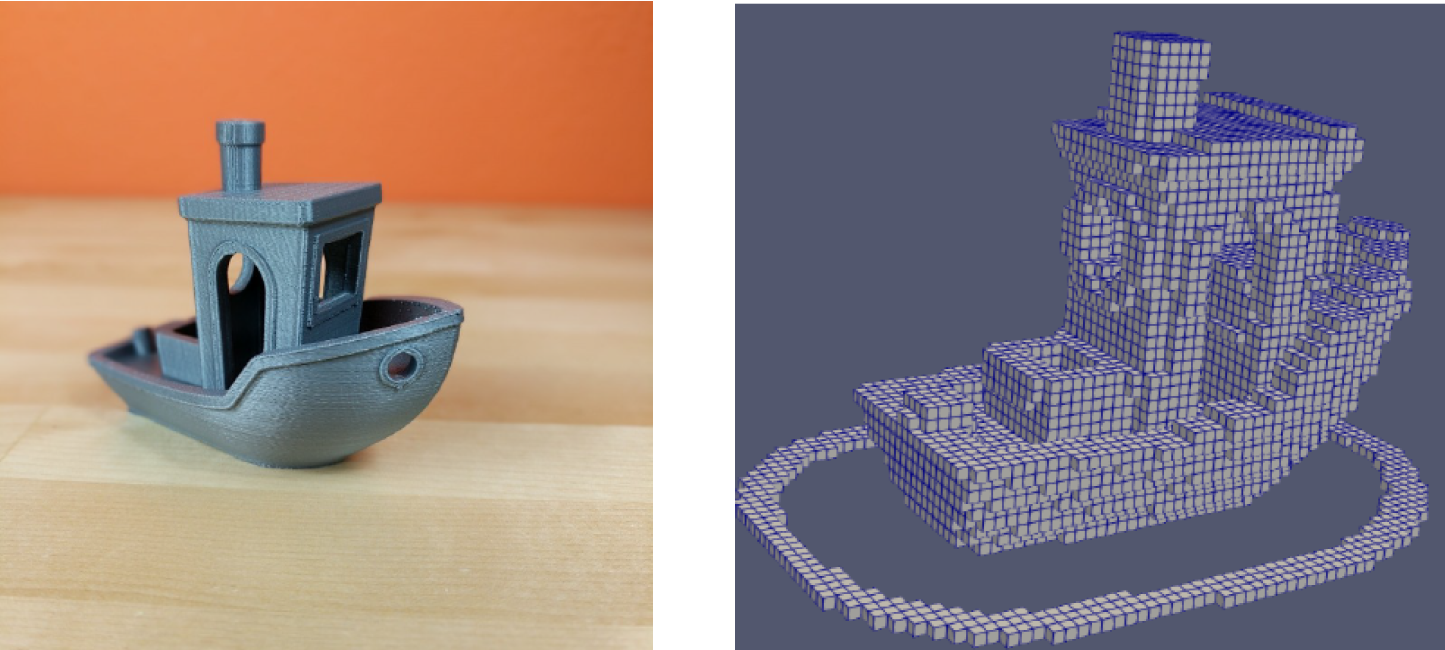

Beat the AI

This project explores rule-based FDM infill strategies using grid models, aiming to outperform AI by reducing moves, material waste, and backtracking on complex geometries printing.

Design and implementation of a learning strategy for neuromorphic soft robots

This project develops bio-inspired learning soft robots by integrating an organic neuromorphic “brain” based on organic electrochemical transistors that process and store sensory information in hardware. Coupled to liquid crystal elastomer actuators, the system enables real-time adaptation of robotic behavior through seamless integration of sensing, learning, and actuation.

Advancing the Mesh: Enhancing Finite Element Tools for Additive Manufacturing

Enhance a Python tool converting G-code to finite-element meshes by adding belt-printer support, improving performance, and building a GUI for realistic additive manufacturing simulations research.

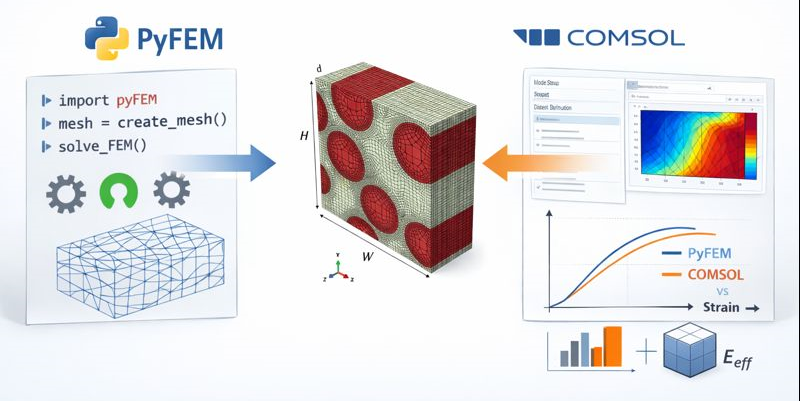

COMSOL vs PyFEM

This Bachelor project compares the open finite-element code PyFEM with the commercial software COMSOL for microstructural materials modelling. The study evaluates modelling flexibility, available material models, numerical performance, usability, and post-processing capabilities using representative homogenization-based case studies.

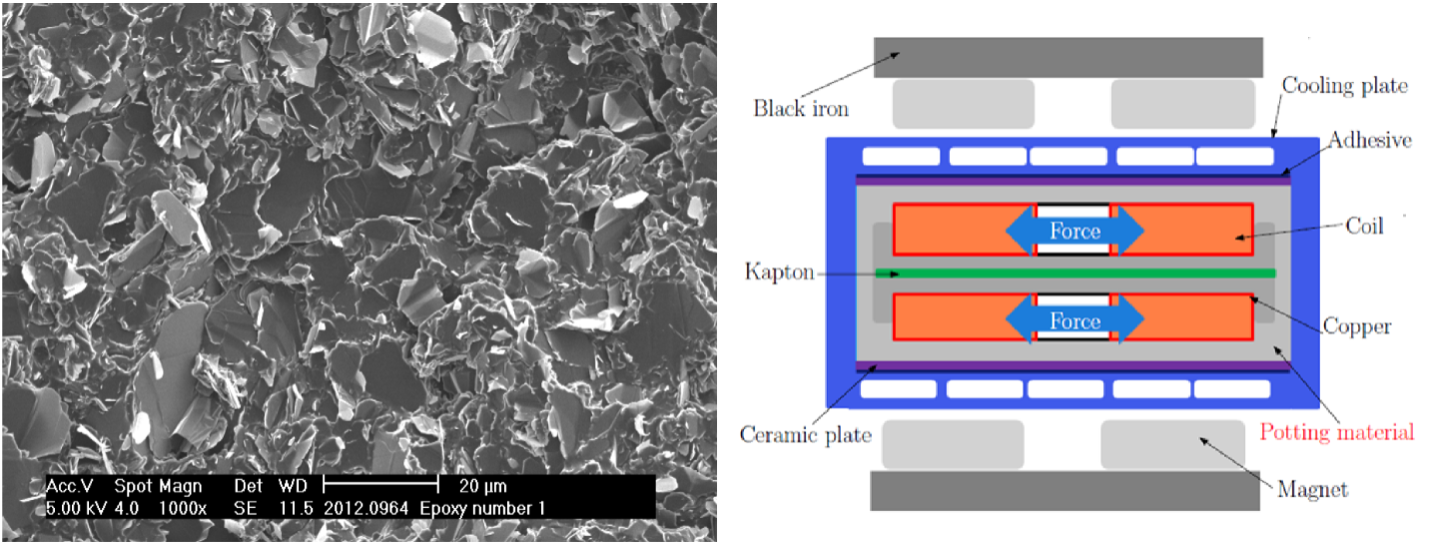

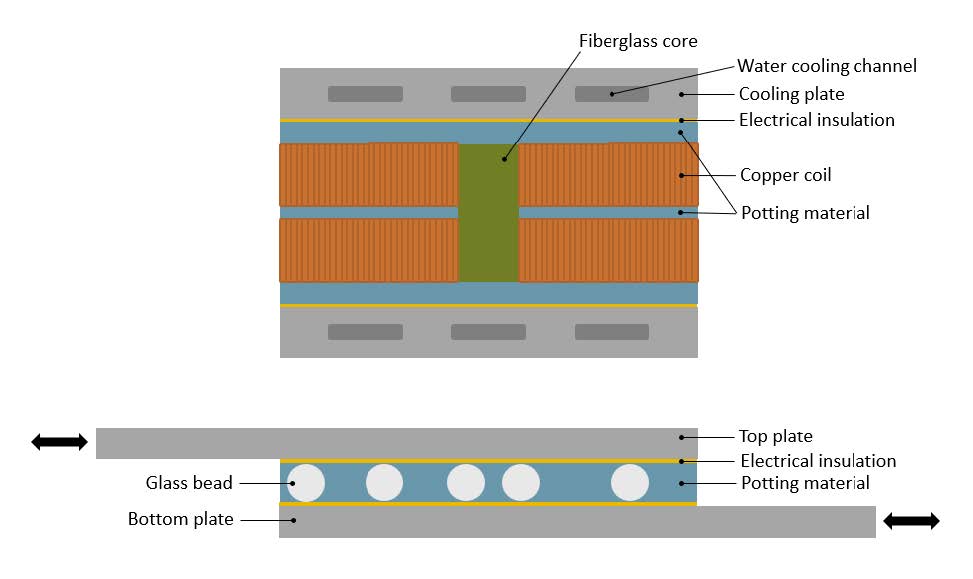

Investigation of the effective thermal conductivity & thermally induced stresses for potting material in electromagnetic actuators

Thermal conduction and the development of thermomechanical stress in heterogeneous potting material used in electromagnetic actuators is simulated using a micromechanical modelling approach.

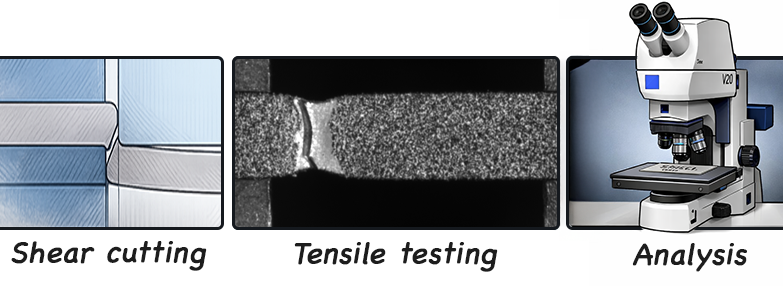

In-situ study of shear cutting effects in Advanced Green Steels

Investigate how shear cutting affects the local ductility and damage evolution of green-produced Advanced High-Strength Steels using in-situ tensile testing and optical microscopy.

Using numerical simulations to understand (and predict!) damage in notched steel bending tests

You will employ and optimize a numerical model to understand and predict damage for notched high-strength steel bending specimens.

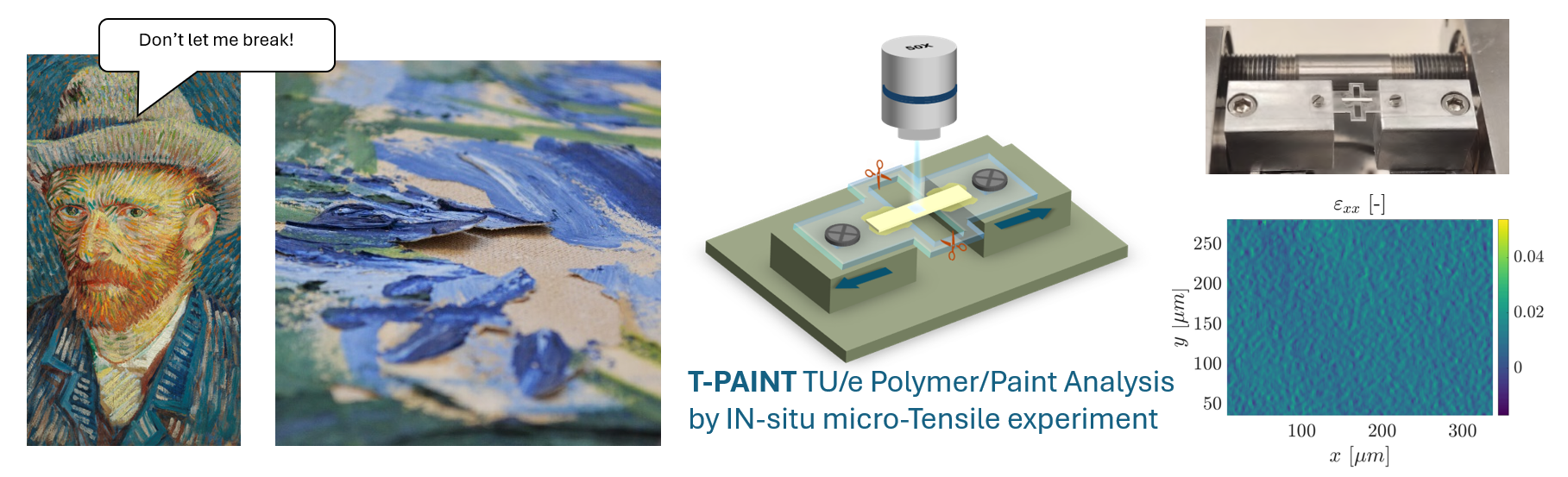

Mechanical properties of oil paints

In this project, we will apply the T-PAINT method on fragile paint samples that are currently being investigated in delamination studies, allowing us to support and clarify the mechanical failure mechanisms of the paint layers.

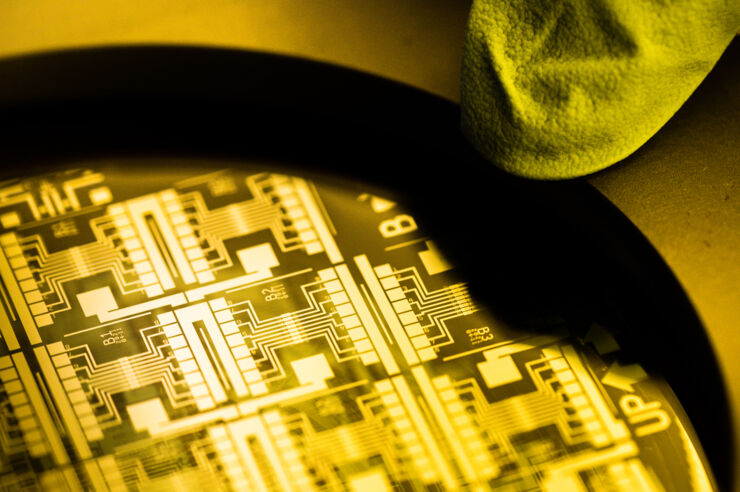

Optimizing Surface Treatments for Electron Microscopy of Green Steel

You will systematically assess and benchmark surface treatment strategies to ensure reliable SEM characterization of nanometer-scale inclusions in advanced high strength steels.

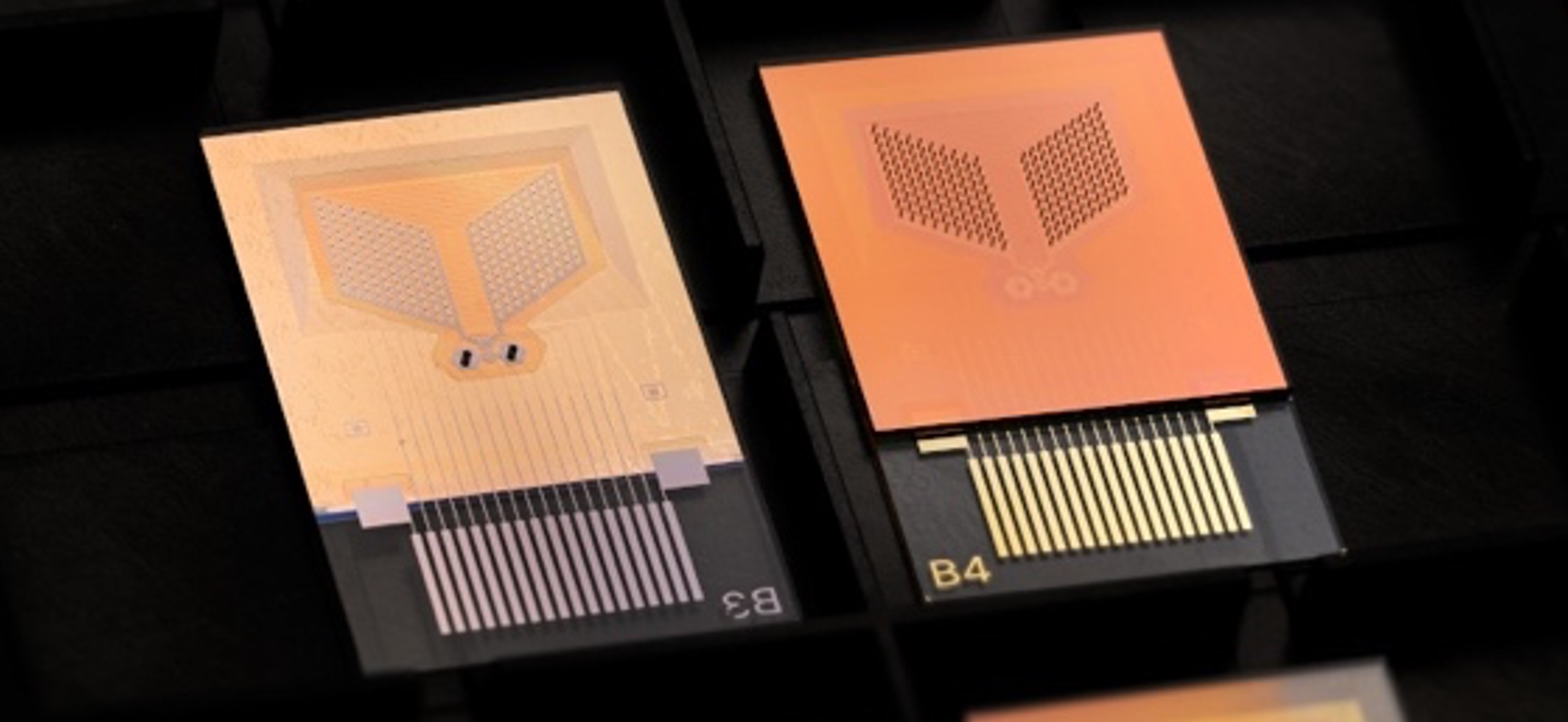

Exploring Frequency Propagation on a Neuromorphic Device

This project explores physics-driven learning in neuromorphic hardware by developing a dual-gate, dual-electrolyte device that enables frequency-propagation–based learning within a single physical element. By combining device design, circuit modeling, and network-level demonstrations, the work aims to realize energy-efficient learning and classification directly in hardware without conventional weight updates.

Photo-patternable Solid Electrolytes for Organic Transistor and Neuromorphic Devices

This project aims to unlock more complex organic electrochemical transistor circuits by developing photopatternable solid-state electrolytes based on semi-interpenetrating polymer networks. By enabling fully solid-state OECTs with improved processability and performance, the work advances OMIEC-based bioelectronic and neuromorphic systems beyond the limitations of liquid or gel electrolytes.

Organic artificial Neurons for Robotic Control

This project investigates post-fabrication electrical and biochemical tuning of organic electrochemical transistors to calibrate organic artificial neurons, enabling precise neuromodulation by biological signals or electronic subsystems. By linking in-hardware device characteristics to neuron and control-system behavior, the work aims to integrate organic artificial neurons into adaptive robotic control architectures.

Spiking Neural Network and Artificial Intelligence applications

This project introduces neuromorphic computing by simulating a spiking neural network and quantitatively comparing its performance and energy-efficiency characteristics to a conventional artificial neural network on a selected task.

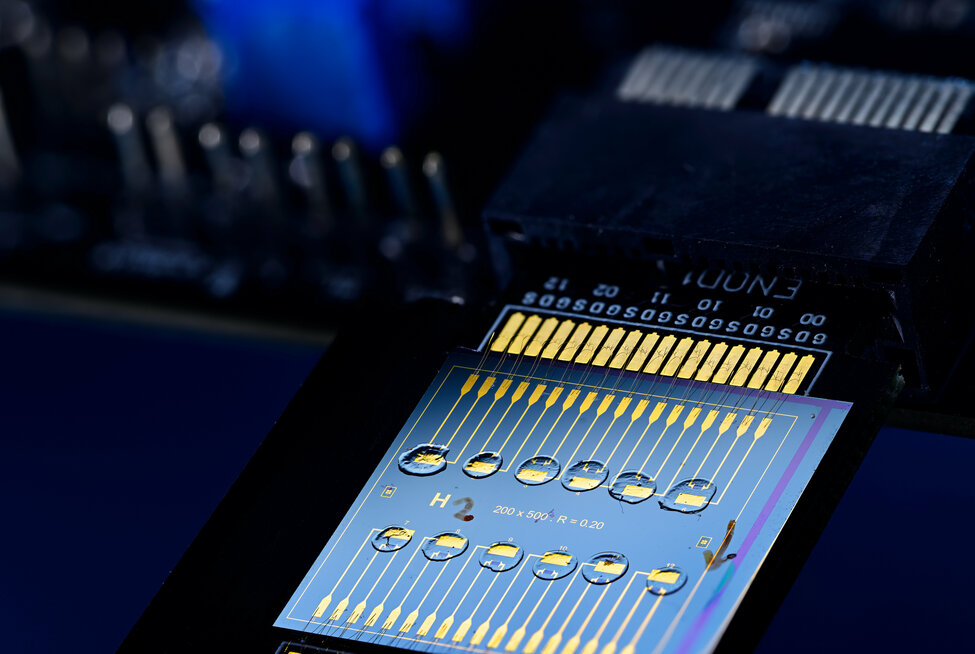

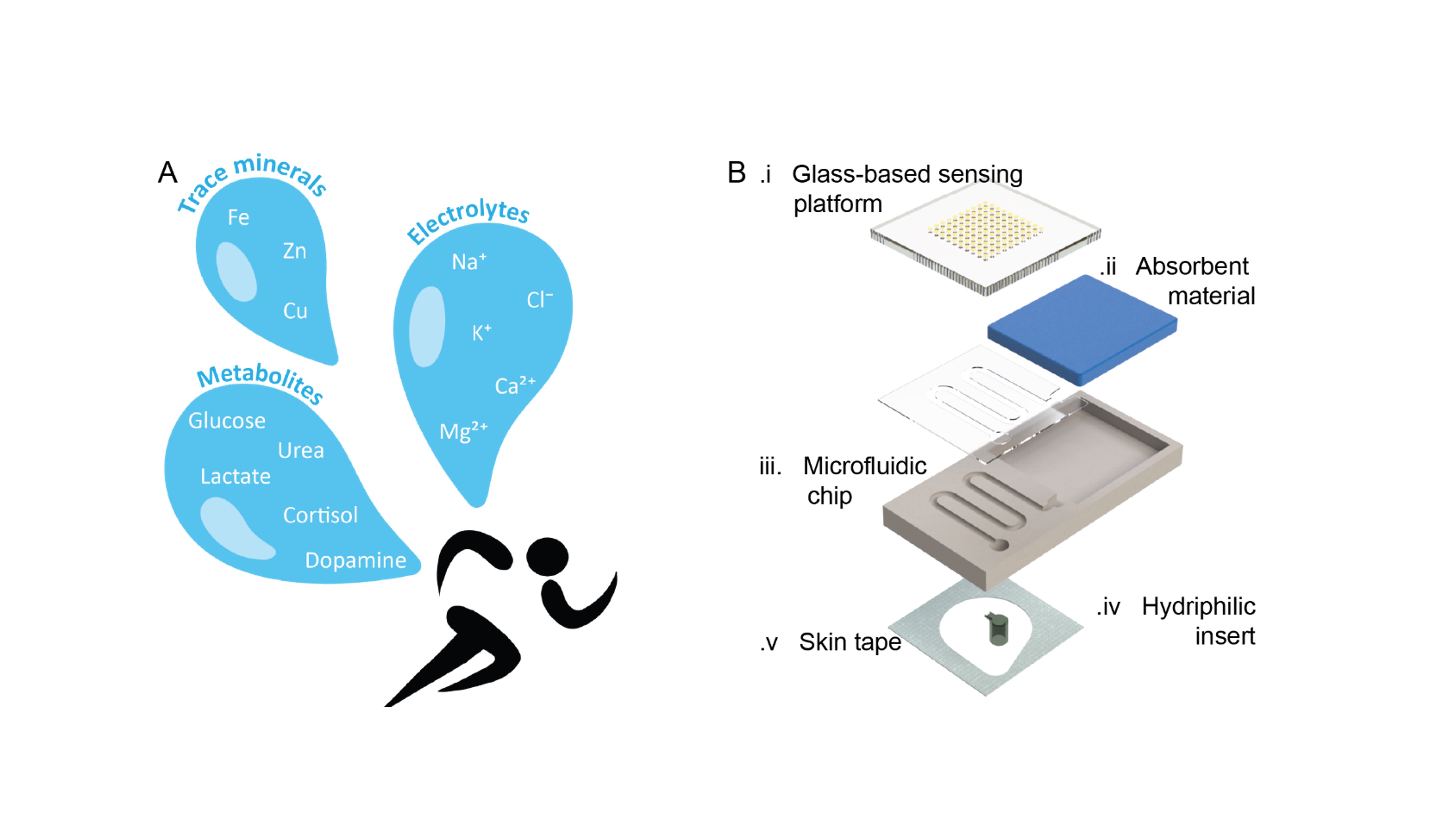

Integrated Sweat Volume and Rate Sensor for Wearable Biomonitoring of Athletes

This project aims to develop a next-generation microfluidic wearable for continuous sweat monitoring by integrating sweat volume and rate sensing. Using passive pumping and electrodes, the system enables accurate, real-time sweat-rate measurement to improve athlete biomarker analysis.

Wearable Microfluidic Device for Time-Resolved Sweat Collection in Athletes

This project aims to develop a wearable microfluidic device to efficiently and accurately collect and store time-resolved sweat samples for athlete biomonitoring, enabling post-exercise analysis to provide deeper insight into sweat composition and its physiological information.

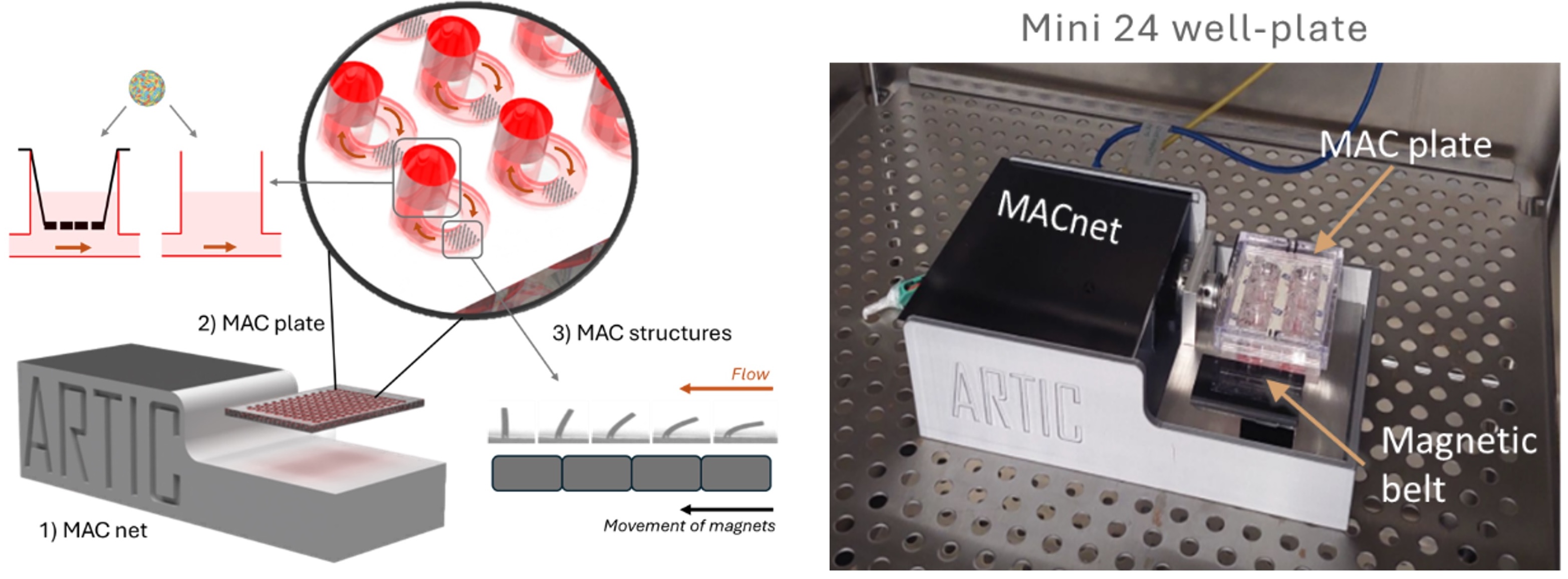

MAC plate: fabrication of an innovative microfluidic cell culture platform with flow

ARTIC Technologies, a spin-off of TU/e, develops novel platforms to create flow for a better drug development. You will be part of our professional team and help us fabricate the platforms for our customers.

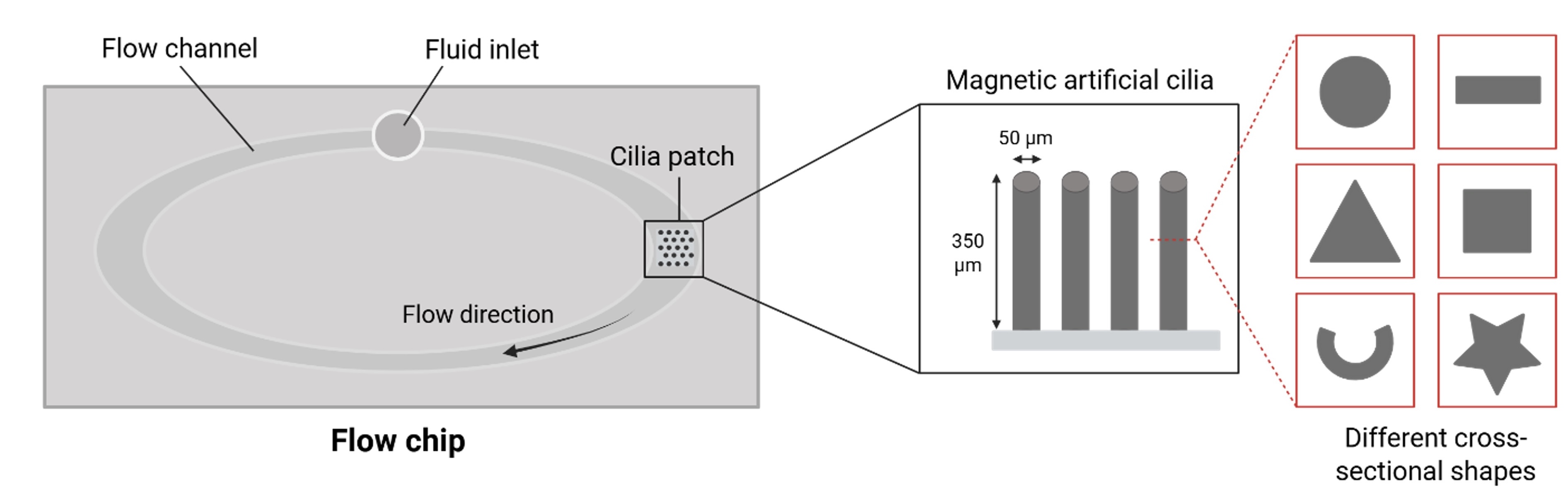

Effects of artificial cilia shape on fluid flow rates

Magnetic Artificial Cilia (MAC) are small, magnetic cylinders nowadays used to pump fluid through microfluidic channels. You will test the effect of various cross-sectional shapes of MAC to enhance fluid flow rate.

Non-invasive kidney function monitoring via sweat sensing

DXcrete is a spin-off company from the Microsystems section, developing a wearable sweat sensing device which enables non-invasive monitoring of patients. The aim of this project is to evaluate and select suitable creatinine sensors for integration into the device.

Modeling of lap shear experiments for potting material used in electromagnetic actuators

Lap shear experiments are modelled in order to obtain insights in the local stress state in the potting material of electromagnetic actuators under applied load.

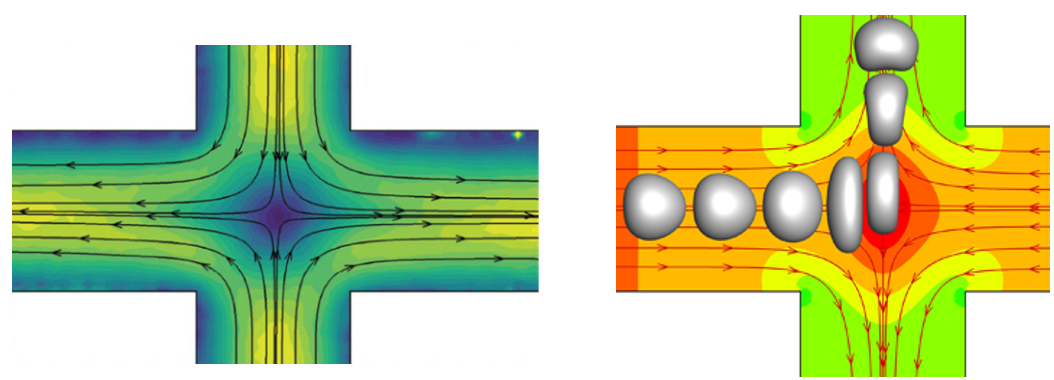

Probing viscoelastic flow with deformable particles: a numerical study in cross-slot geometries

The goal of this project is to numerically study how an elastic particle (modeled as a Neo-Hookean solid) deforms in a viscoelastic fluid in a cross-slot geometry.

Computational Investigation of the Effect of Scanning Strategies on the Thermal Field in Laser Powder Bed Fusion of Tungsten for Nuclear Fusion Applications

A single layer finite element–based thermal model is developed and used to study the effect of different scanning strategies on the thermal field for laser powder bed fusion of tungsten.