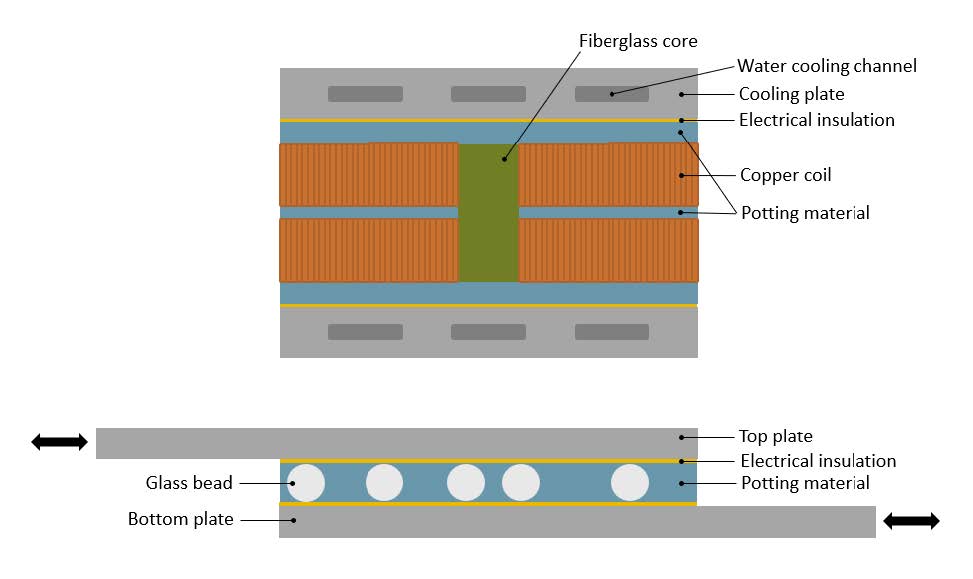

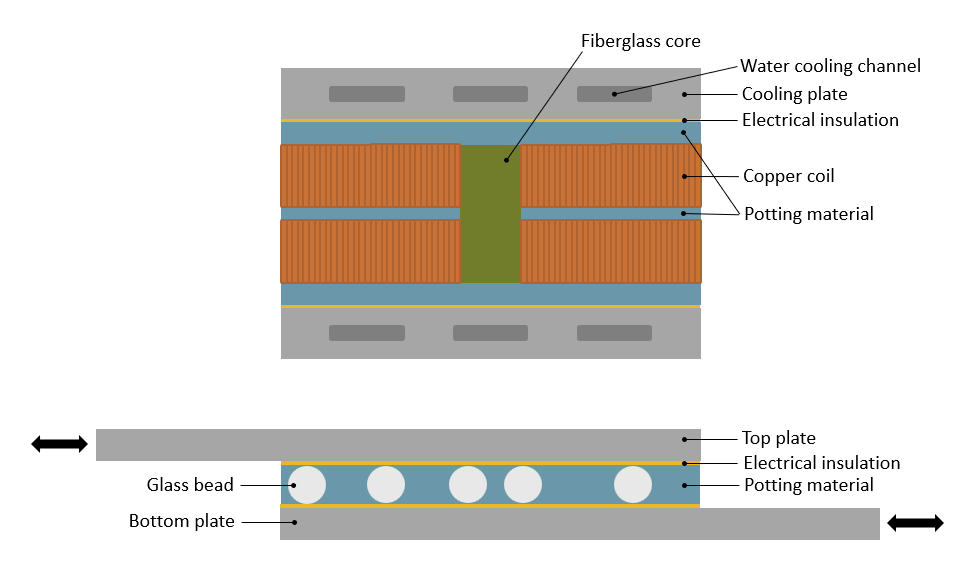

Actively-cooled electromagnetic actuators are employed to facilitate movement in high-tech systems like the EUV lithography machines from ASML. In these actuators, the copper coils used to generate Lorentz forces are suspended in an epoxy-based potting material that serves to dissipate heat to the outside housing. During operation, the repeated thermo-mechanical loading of this material can lead to fatigue cracking resulting in an increase of thermal resistance and ultimately actuator failure.

To investigate the durability of the potting material under load, lap shear fatigue experiments have been performed, for which the samples are illustrated in Figure 1 below. To maintain a constant distance between the top and bottom plate, 1 wt% of glass beads of a desired diameter was added to the material. The goal of the project is to model the lap shear experiments in a finite element package in order to provide insights regarding the local stress state in the potting material under applied load. Hereby, the consequences of the addition of glass beads for this local stress state are of particular interest.

Figure 1: Schematic representation of an electromagnetic actuator cross-section (top) and a close-up of the epoxy joint with glass beads for a lap shear sample (bottom).