As much as 90% of medicines in development fail to go to the market due to the inability of traditional methods, for example animal models, to accurately predict therapeutic responses in humans. Advanced in vitro methodologies, such as 3D cell culture models, are emerging to bridge the gap between animal studies and human trials by accurately replicating human organ biology. Such “microphysiological systems” better mimic human organs and tissues, offering more physiologically relevant and predictive models. Unlike the static nature of traditional systems, physiological flow is crucial in 3D cell cultures to mimic in vivo dynamics, enhancing cell function, viability, and experimental outcomes. At the same time, provide insufficient physiological flow, or rely on very complex microfluidic perfusion systems that introduce a level of complexity incompatible with the standards and demands of the pharmaceutical industry. This mismatch has become a major barrier to the widespread adoption of 3D cell cultures in drug development.

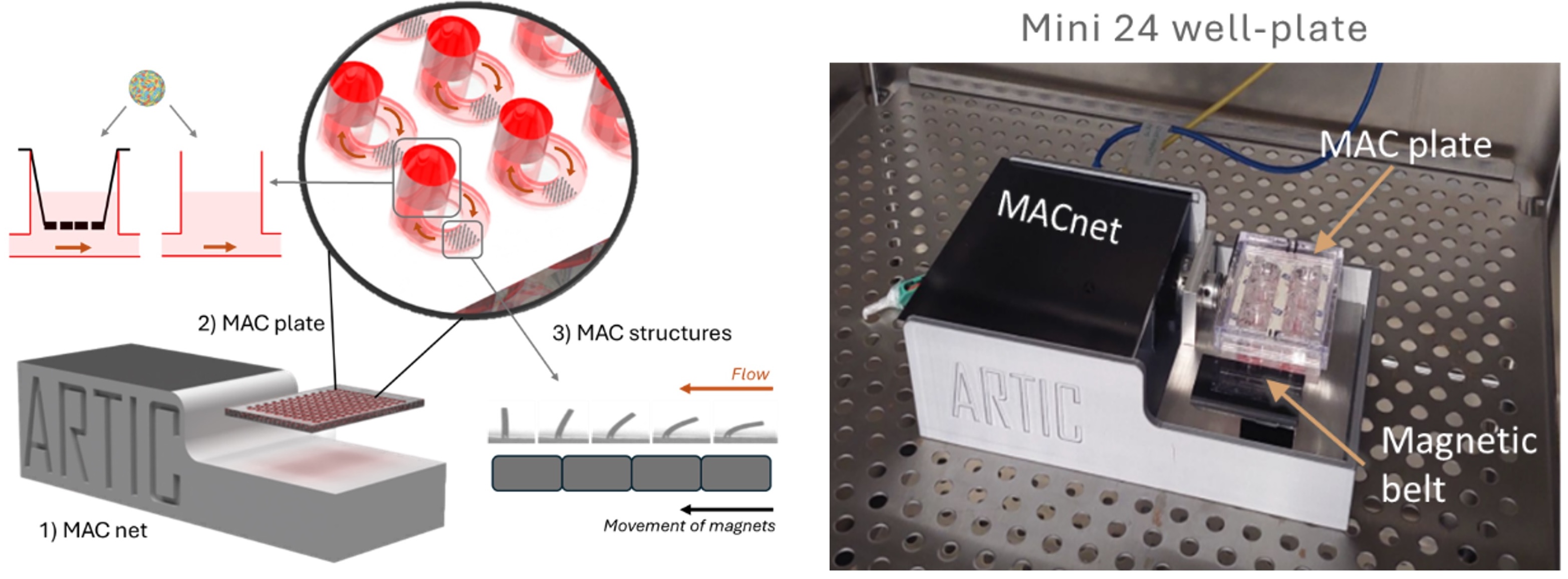

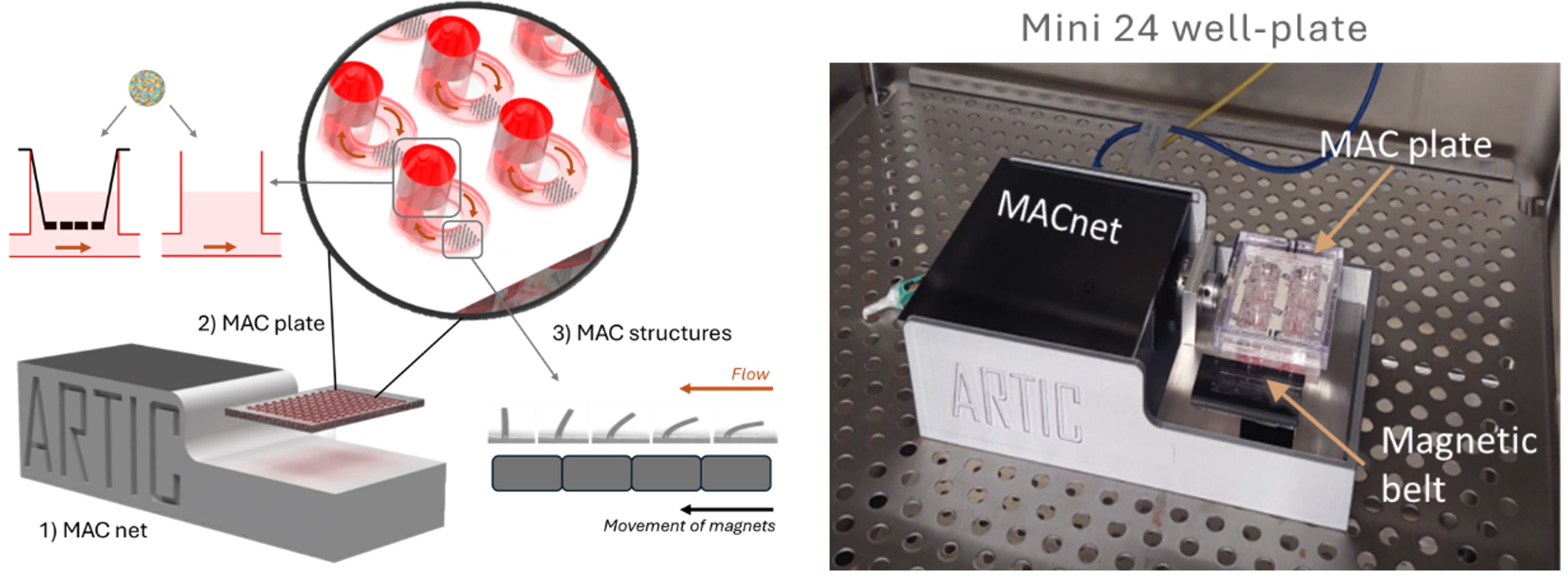

Innovation breakthrough: ARTIC provides a revolutionary flow solution to grow and use cell cultures with its nature-inspired Magnetic Artificial Cilia (MAC) technology. This innovation uses microscopic, hair-like artificial cilia structures, actuated by a magnetic field to achieve high-precision flow control at the microscale. Our innovative platform is called MAC system (figure below) and consists of two parts: MAC plate which is one-time-use microfluidic plate compatible with cell culture standards, and MACnet which is a magnetic actuation system that actuate the MAC integrated in the MAC plate. Our MAC system follows standard cell culture plate standards and integrates seamlessly with automated workflows, promoting its adoption in the drug development industry. The solution reduces costs and eliminates manual handling. We pave the way for widespread adoption of advanced microphysiological systems in drug development, enhancing drug discovery outcomes and reducing industry reliance on animal testing.

In this project, we aim to fabricate and optimize the fabrication of the MAC system for our customer projects. You will be part of our production team at the microfab lab that optimizes the fabrication workflow. You will learn variety of fabrication methods such as laser processing, micromachining, molding and assembling of mechanical systems. You will learn what it means to work in a young and dynamic start-up. Our coffee is amazing and our “borrels” are always fun!

Figure 1. MAC system and the principles of creating flow.