Are you interested in an experimental research project with real-world impact?

To make steel production greener and significantly reduce CO₂ emissions, practices such as steel recycling and hydrogen-based steelmaking are rapidly gaining traction. However, these approaches often reduce control over the exact chemical composition of steels. This increased compositional variability is particularly critical for Advanced High Strength Steels (AHSS), which are widely used in safety-critical automotive components.

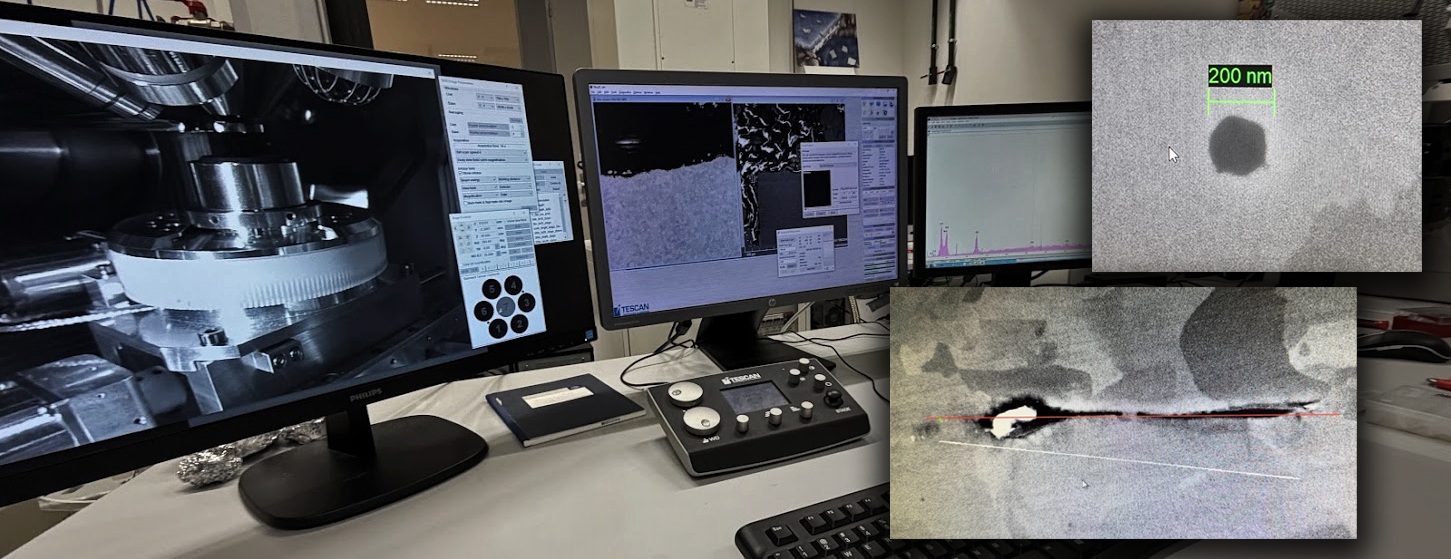

One consequence of this variability is the formation of non-metallic inclusions in the steel microstructure. Larger inclusions (2–10 µm) are well known to be detrimental, causing edge cracking and premature failure. In contrast, the role of smaller, submicron inclusions (200–800 nm) is still poorly understood. Do they contribute to plastic deformation? Do they act as damage initiation sites? Or can they be tolerated without compromising performance?

In our group, we investigate the mechanical role of these inclusions by performing in situ mechanical experiments inside a scanning electron microscope (SEM). This allows us to directly observe deformation and damage processes at the nanometer scale. However, the way test samples are prepared can itself strongly influence the microstructure and, consequently, the experimental results.

In this project, you will systematically study how different sample preparation techniques affect the test specimen and advise how to achieve minimal negative effects.

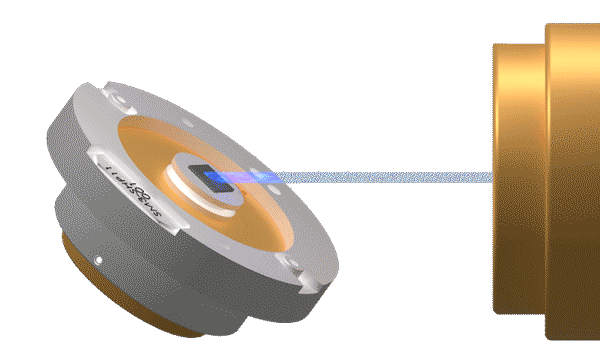

You will work with a broad range of preparation methods, including mechanical grinding and polishing, broad ion beam (BIB) milling, and electrochemical polishing. The resulting microstructural changes will be analyzed using optical microscopy and SEM.

Source: https://www.nanoscience.com/products/broad-ion-beam-polishers/semprep-smart/

Based on your findings, you will critically compare preparation techniques and formulate evidence-based recommendations for minimizing preparation-induced artifacts. Your work will directly contribute to reliable experimentation on AHSS, enabling the development of greener steelmaking routes without compromising mechanical performance.

What you'll do? Hands-on experimentation, microscopy and analysis

What we're looking for? a curious, independent and hands-on student with interest in materials

Are you interested? Or do you have questions about this project? Reach out to Bart Verhaegh (b.j.verhaegh@tue.nl)