Background and Motivation

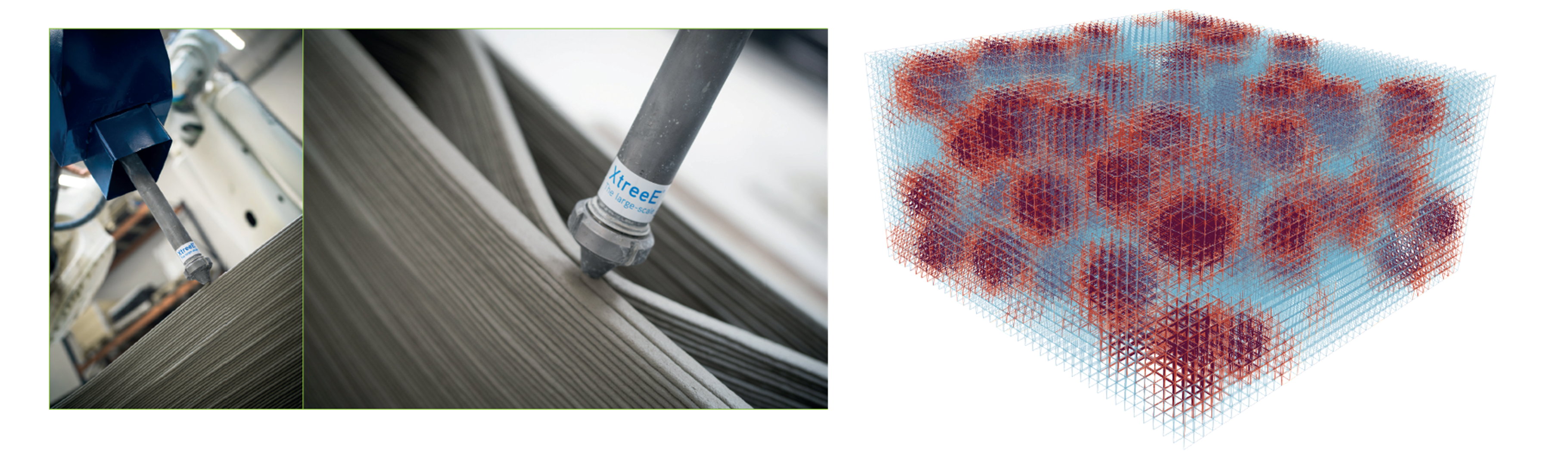

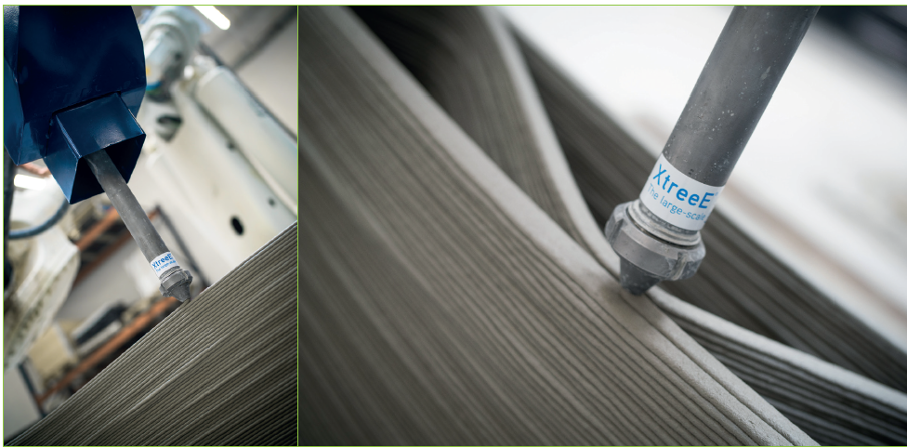

3D-printed concrete (3DPC) is a rapidly emerging construction technology with the potential to significantly reduce material waste and construction time while enabling unprecedented architectural freedom. However, despite these advantages, mechanical performance remains a key bottleneck, mainly due to weak bonding between printed layers caused by the layer-by-layer deposition process.

Fig 1: 3D-printed concrete element produced by XtreeE (source: JEC Composites).

Interfaces between printed layers often contain elongated air voids and particle segregation, leading to anisotropic strength and premature fracture under tensile and flexural loading. Understanding how microstructural features such as particle size and volume fraction govern bonding across these interfaces is therefore essential for improving material design and enabling durable, load-bearing 3DPC structures.

This thesis project offers a unique opportunity to combine state-of-the-art experimental characterization with numerical modeling, allowing the student to directly link microstructural characteristics to macroscopic mechanical behavior.

The main objective of this thesis is to identify and quantify the microstructural parameters that govern interlayer bonding strength in 3DPC and to explore strategies for improving it. The balance between experimental work and numerical modelling can be adapted to the student’s background and interests.

Experimental Track (Hands-on & Materials-Focused)

The experimental track focuses on the characterization of 3DPC specimens with controlled layer interfaces. The student will post-process X-ray CT data of tensile and bending specimens to quantify the three-dimensional pore and particle structure using conventional or CNN-based image segmentation methods. Mechanical testing will be combined with force–displacement measurements and Digital Image Correlation (DIC) to study crack initiation and localization.

Numerical Track (Computational & Modeling-Focused)

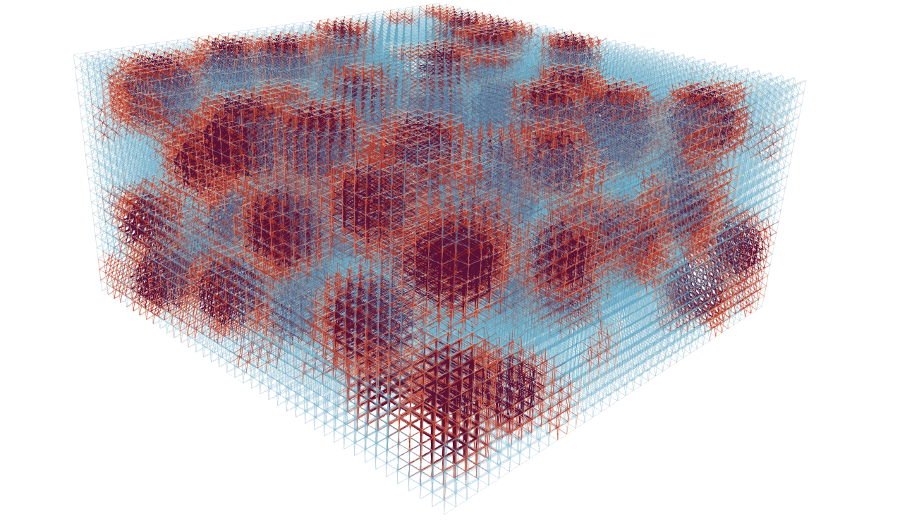

The numerical track is based on an existing discrete lattice modeling framework implemented in MATLAB and C. The student will simulate fracture behavior in 3DPC using discrete lattice representations, with a particular focus on layer interfaces. These regions will be modeled with varying particle volume fractions, particle sizes, and spatial distributions to study their influence on bonding strength. Through systematic parametric studies, the student will identify microstructural features that enhance strength, delay crack initiation, and promote more ductile fracture behavior. Optional extensions include improving computational efficiency or exploring multiscale modeling concepts.

Fig 2: Microstructure-resolved discrete lattice model of 3DPC showing the cement matrix (blue) and embedded aggregates (red).

Combined Experimental–Numerical Track

In the combined track, experimental observations and numerical simulations are tightly integrated. CT-based segmentation results are used directly as input for numerical models, and numerical predictions are validated against experimentally measured force–displacement curves. This approach enables the exploration of “what-if” scenarios that are difficult or costly to investigate experimentally, providing a comprehensive understanding of how microstructure governs bonding performance.