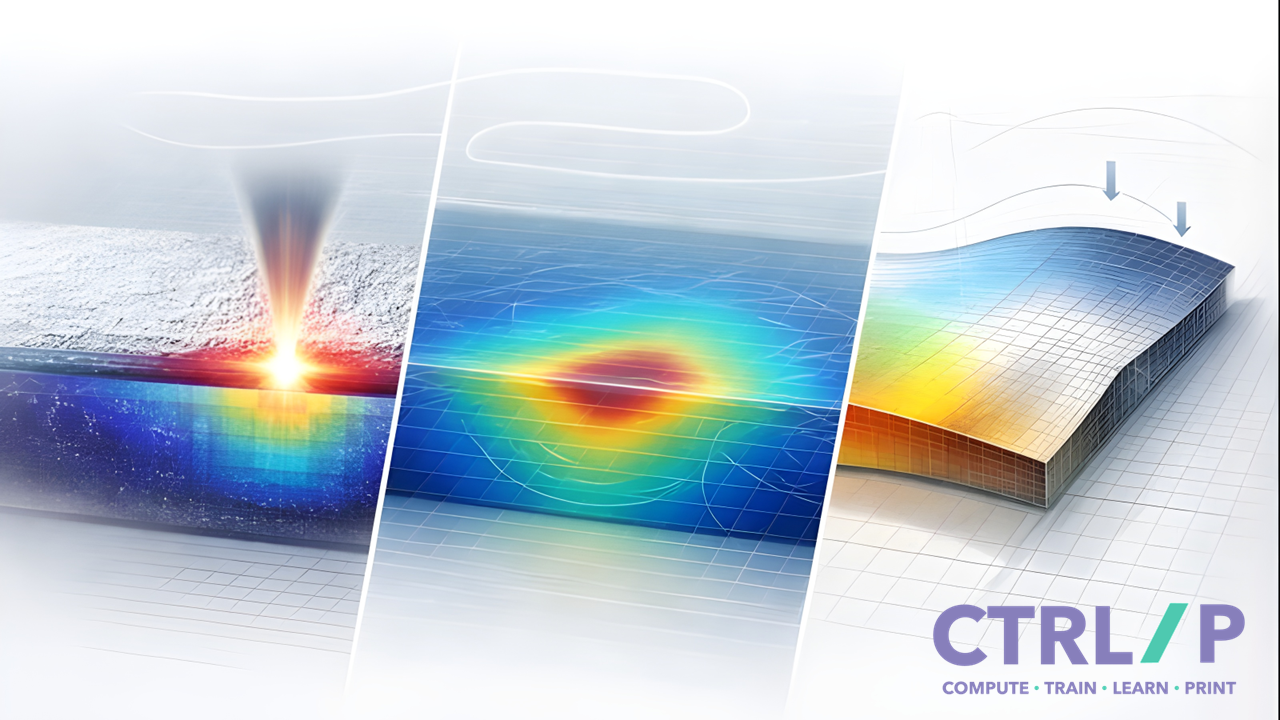

Thermo-mechanical coupling is critical in Powder Bed Fusion (PBF): rapid, localized heating and cooling drives melt-pool formation and can lead to residual stress buildup, distortion, warping, and cracking. Process parameters (laser power, scan speed, hatch spacing) and scan patterns strongly influence the thermal history and stress accumulation.

In this project, you will extend a Python-based FEM framework for thermal simulation and melt-zone tracking by coupling it to a mechanical solver that predicts residual stress and deformation during cooling. The coupled simulator will be used as an RL environment to discover toolpaths and process settings that reduce residual stress and distortion while improving thermal uniformity, and to compare against deterministic scan strategies (zigzag, contour, spiral).

Project objective and approach

Develop a coupled thermo-mechanical FEM solver in Python that computes residual stress and distortion for powder bed fusion. Start with sequential (one-way) coupling: compute time-varying temperature fields from the thermal analysis, then solve the mechanical response using temperature-dependent material properties and thermal strain.

Train an RL agent using the simulator as an environment, learning policies that optimize residual stress, distortion, and thermal uniformity under process constraints; benchmark against deterministic baselines and simple heuristics.

Use sparse matrix techniques and efficient time stepping to keep runtime practical on standard hardware. Validate the thermal and mechanical components against analytical test cases and benchmark the coupled predictions against literature and (where available) commercial software results.

Tasks

Implement a 2D elastic FEM solver (plane stress/strain) with sparse assembly and temperature-dependent properties (E, ν, α).

Implement sequential coupling: read the thermal history, compute thermal strain per time step ( \varepsilon_{th} = \alpha (T - T_0) ), and solve mechanical equilibrium to obtain stress and deformation.

Validate the mechanical solver against analytical beam/plate problems; validate the coupled solver against published benchmarks and/or commercial software comparisons.

Optimize performance: efficient sparse assembly, selective mechanical solves, and reuse of matrix factorizations where possible.

Implement PPO/DQN baselines on the simulation interface; define rewards/metrics for residual stress, distortion, and thermal uniformity; benchmark learning performance and robustness across scan patterns.

References

[1] Liang, X., Chen, Q., Cheng, L., Hayduke, D., To, A.C. (2019). A pragmatic part scale model for residual stress and distortion prediction in powder bed fusion. Addit. Manuf., 22, 589–599. DOI: [https://doi.org/10.1016/j.addma.2018.05.038](https://doi.org/10.1016/j.addma.2018.05.038)

[2] Carraturo, M., Kollmannsberger, S., Reali, A., Auricchio, F., Rank, E. (2022). Thermo-mechanical simulations of powder bed fusion processes: accuracy and efficiency. Adv. Model. and Simul. in Eng. Sci., 9, 17. DOI: [https://doi.org/10.1186/s40323-022-00230-y](https://doi.org/10.1186/s40323-022-00230-y)

[3] Gouge, M., Michaleris, P. (2018). Thermo-Mechanical Modeling of Additive Manufacturing. Butterworth-Heinemann. ISBN: 978-0128113134

[4] RL framework and baselines: ctrlp-zoo (internal) providing PPO/DQN implementations and experiment utilities.