In Powder Bed Fusion (PBF), the laser scan path and settings (power, speed, hatch spacing) determine the temperature history in the part. This temperature history strongly affects residual stress and distortion, which can lead to warping or cracking. Ideally, you want scan strategies that keep the temperature field more uniform and reduce stress build-up.

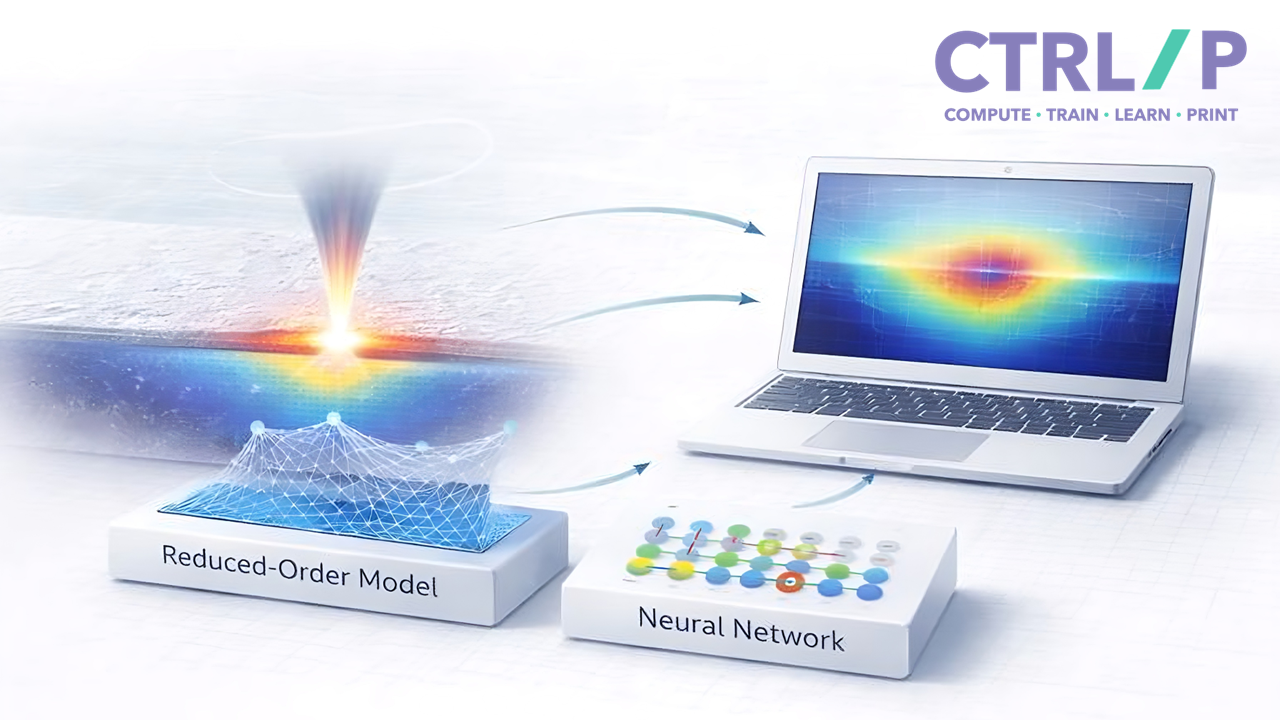

High-fidelity thermo-mechanical FEM can predict these effects well, but it is too slow to run thousands of trials when searching for good toolpaths and parameter settings. This project tackles that bottleneck by building a fast surrogate model that approximates the FEM response. The surrogate will predict the evolution of thermal fields and stress/distortion indicators much faster than FEM, enabling rapid exploration of scan strategies. The best strategies found with the surrogate will then be checked again with the FEM model.

Project objective and approach

Develop a surrogate model of the thermo-mechanical response that is fast enough for many repeated simulations. Two practical directions are:

* **Reduced-order modeling (ROM):** project the FEM solution onto a low-dimensional basis (e.g., POD-Galerkin) or use autoencoders to compress and evolve the field.

* **Physics-guided machine learning:** train a neural surrogate (e.g., UNet-style field predictor or neural operator such as DeepONet/FNO), optionally with physics-based loss terms.

Workflow:

Generate data: run the existing thermal / thermo-mechanical FEM models for a range of scan paths and process settings.

Train the surrogate: learn to predict temperature-field evolution and stress/distortion proxies; quantify accuracy and stability over multiple time steps.

Use the surrogate for optimization: search for scan strategies and parameter settings that reduce residual stress and distortion and improve thermal uniformity.

Validate on FEM: re-run the best candidates on the FEM baseline to verify the achieved improvements and identify when the surrogate is unreliable.

Tasks

Dataset creation: design and run simulation experiments with thermal and thermo-mechanical FEM; store temperature histories and residual-stress/distortion metrics.

Surrogate modeling: implement and train a ROM and/or physics-guided neural surrogate; quantify prediction error and rollout stability.

Integration for optimization: connect the surrogate to the existing optimization/RL framework; define observations, action space, and objective metrics for stress, distortion, and thermal uniformity.

Validation on FEM: evaluate the best surrogate-found strategies on the FEM baseline; report speed-up versus accuracy, robustness, and failure cases.

Optional: active learning loop to add new FEM simulations where surrogate error is high or where the search frequently visits.

References

[1] Liang, X. et al. (2019). A pragmatic part-scale model for residual stress and distortion prediction in PBF. Addit. Manuf., 22, 589–599. DOI: [https://doi.org/10.1016/j.addma.2018.05.038](https://doi.org/10.1016/j.addma.2018.05.038)

[2] Carraturo, M. et al. (2022). Thermo-mechanical simulations of PBF: accuracy and efficiency. Adv. Model. and Simul. in Eng. Sci., 9, 17. DOI: [https://doi.org/10.1186/s40323-022-00230-y](https://doi.org/10.1186/s40323-022-00230-y)

[3] Raissi, M., Perdikaris, P., Karniadakis, G.E. (2019). Physics-informed neural networks. J. Comput. Phys., 378, 686–707. DOI: [https://doi.org/10.1016/j.jcp.2018.10.045](https://doi.org/10.1016/j.jcp.2018.10.045)

[4] RL framework and baselines: ctrlp-zoo (internal) for PPO/DQN and experiment utilities.